The Importance of Separating Plastic Waste

Proper waste segregation is a cornerstone of effective recycling programs. One of the most significant materials that require careful sorting is plastic. In this blog post, we’ll discuss the importance of separating plastic waste to (a) reduce contamination of recyclables, (b) recover plastic waste for recycling into new products, and (c) reduce the amount of new plastic needed.

Reducing Contamination of Recyclables

Contamination is a major hurdle in the recycling process. When plastics are not properly separated, they can contaminate other recyclable materials, making them less valuable and more difficult to recycle.

Impact of Contamination:

- Quality Degradation: Mixed materials can reduce the quality of recyclable items, leading to a higher rejection rate at recycling facilities.

- Increased Processing Costs: Contaminated recyclables require more extensive sorting and cleaning, increasing operational costs.

- Landfill Overflow: High contamination rates mean that more recyclables end up in landfills, exacerbating waste management issues.

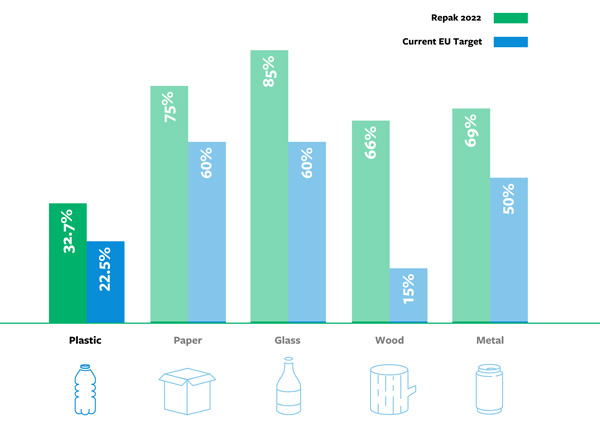

In Ireland, the recycling rate for plastics is currently at 32.7%, which, while above the EU target of 22.5%, still indicates a need for better separation practices to improve overall recycling efficiency (Repak) (TheJournal).

Recycling Targets Ireland vs EU

Recovering Plastic Waste for Recycling into New Products

Proper segregation of plastic waste ensures that these materials can be efficiently processed and recycled into new products. This is crucial for creating a circular economy where materials are reused and repurposed.

Benefits of Recycling Plastic:

- Resource Efficiency: Recycling plastics saves raw materials and reduces the need for virgin plastic production.

- Energy Savings: The process of recycling plastics typically consumes less energy compared to producing new plastics from scratch.

- Environmental Protection: By recycling plastics, we reduce the pollution associated with plastic production and disposal.

In 2021, Ireland recycled 104,016 tonnes of plastic, contributing to a more sustainable management of plastic waste (Repak).

Reducing the Need for New Plastic

One of the most significant benefits of effective plastic recycling is the reduction in the demand for new, virgin plastic. This has multiple environmental and economic benefits.

Advantages of Reducing New Plastic Production:

- Conservation of Resources: Reducing the need for new plastic conserves fossil fuels and other natural resources used in plastic production.

- Lower Carbon Footprint: The production of new plastics is a significant source of greenhouse gas emissions. Recycling plastics helps mitigate this impact.

- Economic Savings: Using recycled plastic in manufacturing can be more cost-effective than using virgin materials, leading to savings for businesses and consumers.

Steps to Proper Plastic Waste Segregation

- Identify and Separate: Clearly distinguish between different types of plastics and ensure they are separated from other waste streams.

- Clean and Dry: Rinse plastic containers to remove food residues and let them dry before placing them in the recycling bin.

- Use Proper Bins: Utilize bins specifically designated for plastics to avoid cross-contamination with other recyclables.

- Educate and Encourage: Raise awareness among household members and the community about the importance of proper plastic waste segregation.

The Importance of Separating Food Waste — Reducing Contamination and Enhancing Composting

Proper waste segregation is a critical aspect of effective waste management. One of the most significant components of this process is the separation of food waste. In this blog post, we will explore how separating food waste can (a) reduce contamination of recyclables and (b) recover food waste for composting, contributing to a more sustainable environment.

Reducing Contamination of Recyclables

When food waste is mixed with recyclables, it can contaminate the entire batch. This contamination makes it difficult, if not impossible, to recycle these materials effectively. Contaminated recyclables often end up in landfills, defeating the purpose of recycling programs.

Impact of Contamination:

- Quality Reduction: Food residues can degrade the quality of recyclable materials, making them less suitable for processing.

- Increased Costs: Contaminated recyclables require additional sorting and cleaning, increasing the costs for recycling facilities.

- Landfill Overflow: Contaminated recyclables often end up in landfills, contributing to waste management challenges.

Recovering Food Waste for Composting

Separating food waste not only reduces contamination but also allows for the recovery of organic materials for composting. Composting is an environmentally friendly way to manage food waste, turning it into valuable compost that can enrich soil and support agriculture.

Benefits of Composting:

- Soil Health: Compost adds essential nutrients to the soil, improving its fertility and structure.

- Reduced Greenhouse Gases: Composting organic waste reduces methane emissions from landfills, a potent greenhouse gas.

- Resource Conservation: Using compost reduces the need for chemical fertilizers, conserving natural resources.

In Ireland, approximately 750,000 tonnes of food waste were generated in 2022. Composting facilities accepted around 590,000 tonnes of organic waste for treatment, showcasing the potential of composting in managing food waste effectively.

Steps to Proper Food Waste Segregation

- Set Up Separate Bins: Use dedicated bins for food waste, recyclables, and general waste.

- Educate Household Members: Ensure everyone in the household understands the importance of separating food waste.

- Use Compostable Bags: Line your food waste bin with compostable bags to make the process cleaner and easier.

- Compost at Home: If possible, set up a composting system at home to manage your food waste directly.

Separating food waste is a simple yet powerful step towards improving waste management. By reducing contamination of recyclables and recovering valuable organic material for composting, we can contribute to a more sustainable environment. Ireland’s progress in recycling and composting highlights the importance of continued efforts in waste segregation. Let’s all play our part in the ‘Sort It’ campaign and make a positive impact on our planet.

#SortItCampaign #FoodWaste #Composting #Recycling #Sustainability #EcoFriendly #WasteManagement #SaveThePlanet

By participating in proper waste segregation, you are not only helping to reduce landfill waste but also supporting a circular economy. Together, we can make a significant difference.

Sort It! Campaign Launch

We’re excited to launch this campaign to promote proper waste segregation and recycling. This initiative aims to raise awareness about the importance of managing waste responsibly to create a sustainable future for Ireland.

Why ‘Sort It’?

Proper waste segregation is essential for effective recycling, reducing landfill waste, and protecting our environment. When waste is sorted correctly, recyclable materials can be efficiently processed and reused, minimising environmental pollution and conserving natural resources.

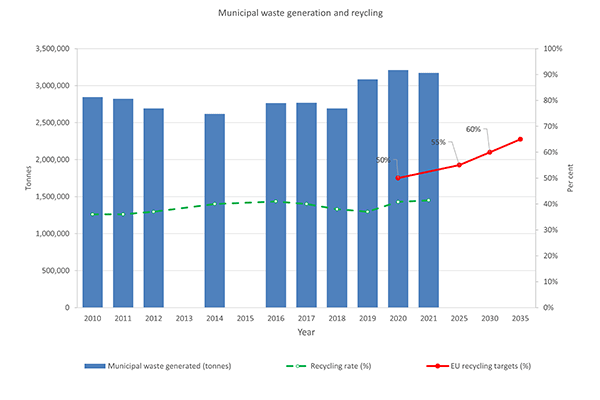

Ireland’s Recycling Landscape

Despite Ireland’s strong track record in recycling, there are challenges ahead. In 2021, Ireland generated 3.17 million tonnes of municipal waste, with a recycling rate of 41% for this waste stream. Packaging waste recycling rates stood at 58%, a decrease from previous years.

Key Statistics:

- Glass Recycling: 85%

- Paper Recycling: 75%

- Plastic Recycling: 32.7%

- Metal Recycling: 69%

- Wood Recycling: 66% (Repak).

While these rates are impressive, there is still room for improvement, especially in meeting the EU’s future recycling targets. Ireland aims to recycle 50% of all plastics by 2025 and 55% by 2030 (TheJournal).

What to Expect

Over the next three months, we will share informative posts, tips, and success stories to help you become more recycling proactive. From understanding recycling symbols to learning how to compost, we’ve got a range of topics lined up to empower you with knowledge and practical advice.

Join Us in Making a Difference

Together, we can create a cleaner, greener future. Follow our campaign, share your recycling tips, and let’s sort it out for a sustainable tomorrow!

Get Involved:

- Follow Us: Stay updated with our latest posts and tips.

- Share Your Story: Use the hashtag #SortItCampaign to share your recycling journey.

- Spread the Word: Encourage your friends and family to join the campaign.

#SortItCampaign #RecycleRight #WasteManagement #GoGreen #EcoFriendly #ReduceReuseRecycle #SaveThePlanet #ZeroWaste

By participating in the ‘Sort It’ campaign, you are taking a step towards a more sustainable future. Let’s work together to make a significant impact on our environment!

Oranmore Recycling Day 2024

FRIDAY JUNE 7 / 10am–4pm

THE CITY BIN CO. RECYCLING CENTRE, ORANMORE H91 EVW3

We’re supporting National Food Waste Recycling Week by hosting a recycling day this Friday June 7.

The perfect opportunity to declutter your home with a clear-out – while responsibly disposing of bulky waste materials!

WHAT TO BRING?

- Any large / bulky items

- Take advantage of free recycling options available for glass, clothes

- And remember that all electrical (WEEE) items (Household items with a plug, including old washing machines, TVs, IT equipment, and mobile phones), are taken free

WE’LL ALSO HAVE…

- Our mobile security shredding unit will be on-site Shredding personal documents for free

- We’ll also have some free Kitchen Caddies to give away on the day

- And we’ll have some free bags of Compost, but when they’re gone, they’re gone – so get there early!

Tiglin’s ‘shining’ example

TIGLIN provides assistance to those in need. From 28 Pearse Street and operating a 7 day a week day service onsite looking after the needs of some of the most vulnerable people in our community while offer food to take away to over two hundred meals to people in homelessness, poverty & addiction. A lot of the donations come on a daily basis by the wonderful people at Foodcloud.

We first made contact with Tiglin when a tweet was picked up by our marketing team. Tiglin had huge frustrations with the cost of their waste and how it was being handled. Small bins, all general waste, being contaminated by the public was a particular recurring problem. The City Bin Co.’s John Farrell went to meet the front man of this organisation Ger Ganly and discussed how we could help them to take a more sustainable approach with their waste management.

The result is that The Light House now has bins that are fit for purpose, with locks on them that people can’t ‘flytip’ into anymore. They have also added a compost bin to help with the segregation of this waste. The team is committed to their Earth Day Pledge and as a result of our work here, Tiglin have engaged with The City Bin Co. across all their sites.

Ger Ganley – A Unique Perspective

My name is Gerard Ganley and I have the unique opportunity of working and helping two amazing charities called Tiglin Challenge & Dublin Christian Mission. Tiglin Challenge & Dublin Christian Mission have services that help people who are disadvantaged and often crippled by addiction, homelessness, mental health issues. Dublin Christian Mission is mainly based in Dublin and Tiglin has services in Dublin, Wicklow & Kildare.

We recently had a waste management/collection issue at one of our premises and our Chairman Aubrey Mc Carthy reached out to waste management companies via social media twitter to ask for help. The City Bin Co. and particularly John Farrell (Client Innovation Manager) got back in contact with us to help and during our conversations John and the company have agreed to support us and help us with reducing our general waste and become much more greener to the environment. When I first discussed about trying to reduce waste, damage to environment and costs it was a no brainer to take this support and help.

This opportunity to reduce, recycle waste and be friendlier to society made me think of when I was 14 years old and losing my father and taking the wrong road that was leading to many wasted years of drug addiction. For many of those years I was very often told by others that I was a waster, I believed most times that I was a waster and felt like a piece of rubbish. From the age of 14 years old to the age of 28 years old I lived for drugs, my life was controlled and consumed by drugs and alcohol. I was a chronic heroin and crack cocaine addict at a young age of 22 years old. Life became more and more of a mess as the years rolled on and at age 28 years old I had became homeless on the streets of Dublin, and life was extremely difficult. I had decided through the help of a few individuals that I would get treatment and seek help. I went to a similar program as Tiglin and found a life beyond addiction thank God. Throughout the years since completing that residential program I’ve completed 2 higher diplomas, a degree, got married and have three beautiful children. I’ve worked helping those who have been crippled by addiction and who feel that their life is wasting away or like my own story maybe feel like a piece of rubbish. I never in my wildest dreams thought that my life could be changed and that I could become very useful in life.

It’s amazing to see how waste can be recycled and used again. And a similarity of what was once waste or useless can be useful again!

If you would like more information on the Zero Project, please contact John Farrell, The City Bin Co. email john@citybin.com

Fold Housing’s Zero Pledge

FOLD Housing provides apartments and houses for older people and families. In addition, the Association provides supported housing with 24 hour care for frail and older people.

FOLD Housing enhances the quality of life for many people in the community by providing a unique combination of accommodation and associated service options. These include: Housing-with-Care and day care for frail older people and people with dementia; sheltered housing; and general needs accommodation for families.

The Fold Housing Team

We met with the Fold Housing Team earlier this year to investigate a better more inclusive way to recycle. We focused on two brand new developments in the Citywest part of Dublin namely Cuil Duin and The Mews. Both sites cater for approximately 25 units.

Karen Murphy is the Estate manager that introduced us to her team and worked with The City Bin Co.’s John Farrell to find a better and more cost-effective way to handle their waste.

- We are currently testing the use of organic bin caddies in all of the units along with the use of a recycling bag to move waste

from each unit to the bin stores. - The bin stores now have a general waste bin, a recycling bin, an organic bin and a glass bin.

- All bin stores have clear signage that show what can go into each bin.

- The difference is now significant with binstores achieving over 40% less general waste in the bins.

- The opportunity to recycle has been embraced by all of the teams and is proving to be a big success.

The adoption of the Earth Day Pledge with the group of committed people in Fold Housing will only send the recycling statistics one way. The pledge will be extended across the full portfolio of sites over the next 12 months.

The goal is to achieve a greater recycling rate, a greater understanding of the significance of recycling to achieve the ‘Zero Waste to Landfill’ Accrediatation.

If you would like more information on the Zero Project, please contact John Farrell, The City Bin Co. email john@citybin.com

Knight Frank continue their ‘Journey to Zero’

We engaged with the Knight Frank Green Team onsite at their HQ 6 months ago to investigate a way to handle their waste streams in a more effective manner.

Knight Frank’s senior management team under the supervision of Alison O Neill (Associate Director Property Asset Management) decided to investigate a way to recycle more and work to a ‘Zero Waste to Landfill’ goal. A key part of this process was meeting with The City Bin Co. to understand how waste is being created in the building. A major issue was the non-labelling of bins and no other option available than the ‘black sack’.

Knight Frank’s Rowena Crowley (Director Property Asset Management) and Anna Koczarska (Facility Manager) with The City Bin Co.’s John Farrell.

Progress over the past few months…

- the introduction of recycling bags

- a new organic separation system the implementation of a compost bin along with the introduction of a glass bin.

- Knight Frank now provide a breakfast and lunch option to all their team at HQ. This reduces the amount of waste being brought in at lunchtime and increases the amount of items being recycled.

The impact of this has been significant…

- They have moved from all waste going to landfill to an effective recycling rate of 69% (as of 31.03.23).

- The team are now better aligned with achieving the goal of Zero Waste to Landfill.

If you would like more information on the Zero Project, please contact John Farrell, The City Bin Co. email john@citybin.com

10 ways that businesses can benefit from embracing ‘Earth Day’

Earth Day is celebrated annually on April 22nd, and it’s a day to raise awareness about environmental protection and sustainability. While it’s traditionally been viewed as a day for individuals to make small changes to reduce their environmental footprint, businesses can also benefit from embracing Earth Day. In fact, businesses that prioritise sustainability and environmental protection are more likely to attract and retain customers, improve their brand reputation, and save money on utilities and materials.

In this blog post, we’ll explore 10 ways that businesses can benefit from embracing Earth Day, from enhanced corporate social responsibility to access to new markets and increased employee engagement. Whether you’re a small business or a large corporation, there are many ways to celebrate Earth Day and reap the rewards of a sustainable business model.

Enhanced Corporate Social Responsibility: Celebrating Earth Day can help businesses highlight their commitment to sustainability and environmental protection, improving their Corporate Social Responsibility (CSR) image.

Improved brand reputation: By embracing Earth Day, businesses can show that they are committed to protecting the environment and reducing their carbon footprint, which can lead to improved brand reputation among customers, investors, and other stakeholders.

Cost savings: Businesses that embrace Earth Day can identify and implement sustainable practices that can reduce energy and water consumption, lower waste disposal costs, and save money on utilities and materials.

Increased customer loyalty: Consumers are increasingly aware of the importance of environmental protection and sustainability, and they prefer to do business with companies that share their values. By embracing Earth Day, businesses can attract and retain environmentally conscious customers.

Access to new markets: Some consumers and businesses are willing to pay a premium for environmentally friendly products and services. By embracing Earth Day, businesses can tap into this growing market and expand their customer base.

Employee engagement: Celebrating Earth Day can improve employee morale and engagement by giving employees a sense of purpose and pride in their work. Employees are more likely to be loyal to companies that prioritize sustainability and environmental protection.

Regulatory compliance: Celebrating Earth Day can help businesses stay ahead of regulatory requirements and comply with environmental regulations. Implementing sustainable practices can also help businesses avoid fines and penalties.

Innovation: Celebrating Earth Day can inspire businesses to innovate and develop new sustainable products and services, leading to new revenue streams and a competitive advantage.

Partnerships and collaborations: Embracing Earth Day can help businesses build relationships with other organizations, such as environmental NGOs and government agencies, and collaborate on sustainability initiatives.

Long-term viability: Embracing Earth Day is not just good for business in the short term, but it also helps ensure the long-term viability of the company by protecting the environment and preserving natural resources for future generations.

—

To see how The City Bin Co. can help with your journey to greater sustainability please contact us

23 Sustainability Tips for 2023

It’s easy to hop on the Sustainable Living bandwagon, and what perfect timing to set sustainability goals as your New Year’s Resolutions, but do you really know why we should be trying to live more sustainably?

Our planet can only produce a finite number of resources – from food to water – and can only withstand a certain degree of greenhouse gas emissions to stay healthy. We only have one Earth and are utterly dependent on it for our survival and well-being. At the moment, we are producing resources, using energy, and creating waste at a rate which isn’t sustainable. People and nature will face severe consequences if our current consumption increases.

Living sustainably is a lifestyle that reduces our environmental impact in many ways, from the food we buy to the daily commute. By making some small changes to your lifestyle, you can reduce your carbon footprint and help to tackle these issues. You simply need to do whatever works for you and remember that the small things matter.

So, here are 23 easy ways to become more sustainable in 2023:

At Home

- Reduce your food waste. Read our blog post for easy ways to reduce food waste at home.

- Proper waste management – recycle and dispose of waste correctly.

- Use LED lighting or CFL bulbs instead of incandescent lighting as it is proven to last longer, which reduces the need to keep purchasing light bulbs.

- Open your blinds and use as much natural light as possible before switching on your light bulbs.

- Turn off your lights when you leave a room.

- Purchase recycled toilet paper with plastic-free packaging.

- Repurpose glass jars. Glass jars are a perfect way to store any homemade jam, sauces, or chutneys.

- Start composting. Learn more about composting at home here.

- Recycle your devices when ready to dispose of. You can donate your old devices to schools and other institutions or drop them to our recycling centre free of charge.

Fashion & Beauty

- Buy second-hand clothes where possible. Invest in better quality items that last longer. Slow fashion trumps fast fashion.

- Choose fashion labels that upcycle waste instead of using virgin materials.

- Upcycle old clothes into new garments. For example, a dress you do not wear can be upcycled into a top and skirt. Instead of throwing away damaged clothing, acquire basic sewing skills to patch holes and sew buttons back on. Or if you have a bigger job, take to an alterations shop.

- Donate your unwanted clothing to give it a second life.

- Choose sustainably packaged beauty products.

- Ditch single-use cotton pads from your makeup routine. It takes 20,000 litres of water to produce just one kilogram of cotton. Switch to a reusable alternative such as muslin cloths or other reusable materials – there are lots of options out there!

- Consider using shampoo bars to reduce packaging.

College & Work Life

- Go paperless with your notetaking! Use your phone, tablet, or computer for taking any notes.

- If you do need to print, use both sides of the page.

- Turn off your computer before leaving (or finishing if you WFH!) work

Lifestyle

- Use stainless steel drink bottles instead of plastic bottles.

- Stop buying birthday, Christmas and thank you cards! Make a hand-written note from recycled materials, these are much more meaningful.

- Choose a sustainable keep cup for your coffee.

- Use public transport. It’s also an excellent opportunity to catch up on reading and other things you couldn’t do if you were driving.

We hope you find some of these sustainability tips helpful and easy to work into your own lifestyle and New Year’s resolutions. If we work together, these small sustainable changes will make the world of difference.

Jazz Pharmaceuticals: The Science of Sustainability

Jazz Pharmaceuticals is an anchor tenant in the main building occupying a number of floors at Waterloo Exchange. The corporate headquarters are located in Dublin, Ireland, with offices spanning the globe from Vancouver to Italy. Jazz is committed to creating a company where the culture reflects three important goals – their purpose to serve patients, be a great place to work, and to live the core values of integrity, collaboration, passion, innovation, and pursuit of excellence.

Why start on this sustainability journey?

Being an anchor tenant in this building Jazz Pharmaceuticals immediately engaged in the Earth Day vision for the building in conjunction with the building manager Martin Carroll of Knight Frank. Knight Frank enjoyed a successful Earth Day last year with another one of the Davy portfolio at 45 Mespil Road Dublin 4. Alison O Neill (Head of Property and Facility Services) introduced The City Bin Co. to the Estate Manager Martin Carroll as they felt a different approach to waste management was possible

The journey within this building started from the time they moved in to consistently innovating change in relation to how waste in handled onsite. Stephen Bateson (Global Workplace Manager, Jazz Pharmaceuticals) and his team have created real change in their workplace to avoid unnecessary waste. In working with The City Bin Co. they have been able to identify clear ways of reducing waste.

Some of these initiatives for change were…

- A town hall meeting was arranged in January 2022 with both the corporate tenants in the building along with the high street traders. The key focus of this meeting was to get agreement for a way forward from all parties that this needed to change and everyone needed to take personal responsibility for their own waste streams.

- Removing black sacks from the cleaning process.

- A solution was found to repurpose old IT equipment.

- Knowing exactly where their bins are and only using recycling, glass and organic bins.

- The removal of desk bins and replacing them with pods of bins on each floor.

- The use of ‘paper only’ recycling bins for all shredded waste.

- If fruit is left over on a Friday, staff are encouraged to bring it home rather than dump it.

What was done & by whom?

Stephen Bateson (Jazz Pharmaceuticals Global Workplace Manager) and his team.

The results?

- Plastic bottled water is no longer used onsite as all staff now have reusable water containers. This has saved over 5,000 plastic bottles last year alone.

- With the exception of wipes and face masks due to Covid, all waste now is either recycled, or disposed of as organic waste.

- Awareness to the team of how to, and why to, recycle

What next?

- To share these successes and future goals internally, and to see how these achievements can be replicated across the other locations.

- To maintain the standard they have achieved and measure against this on a quarterly basis

-

To continue to share their story with their customers.